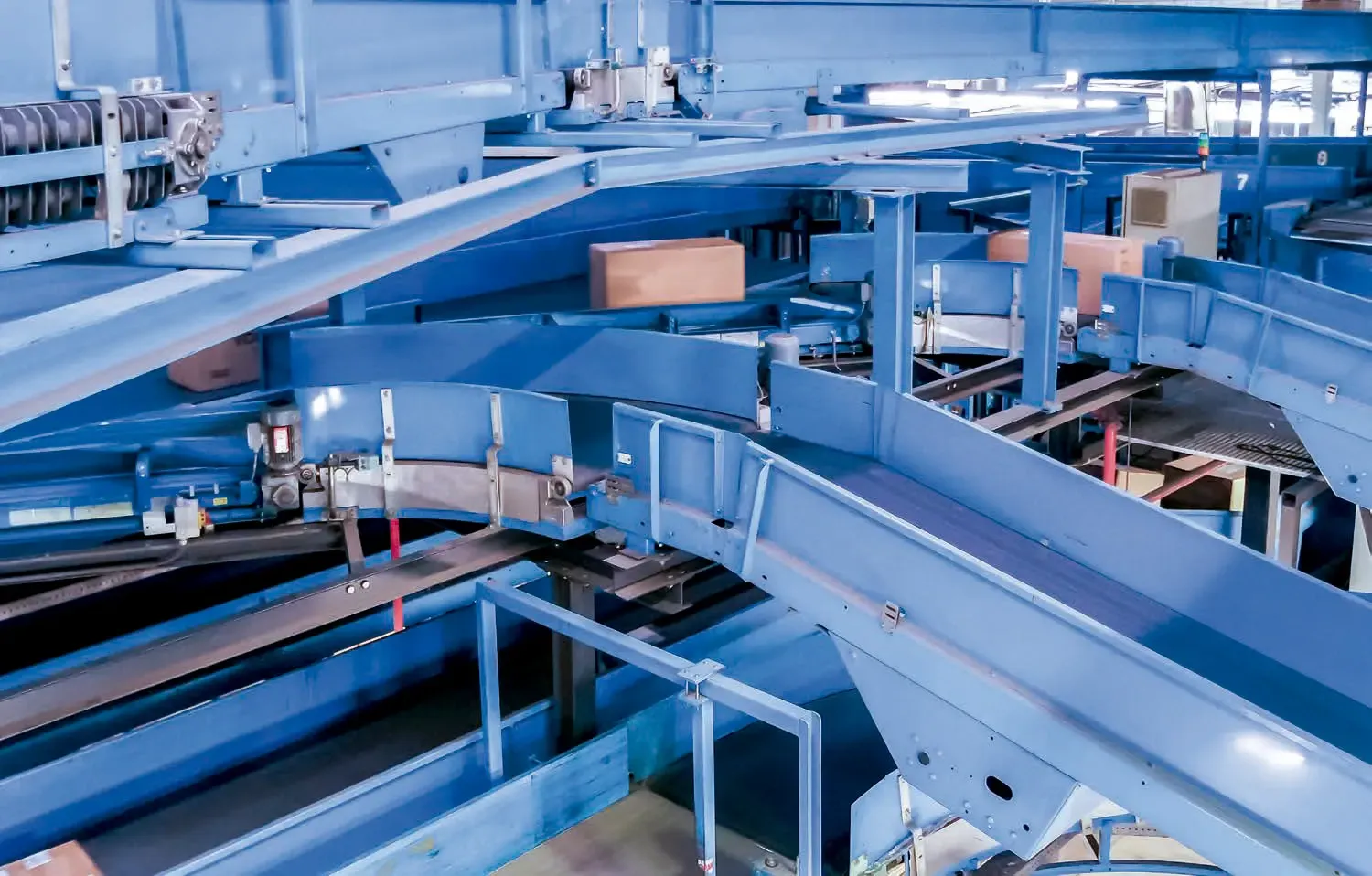

2C Conveyor belts: Innovation for intralogistics and the food Industry

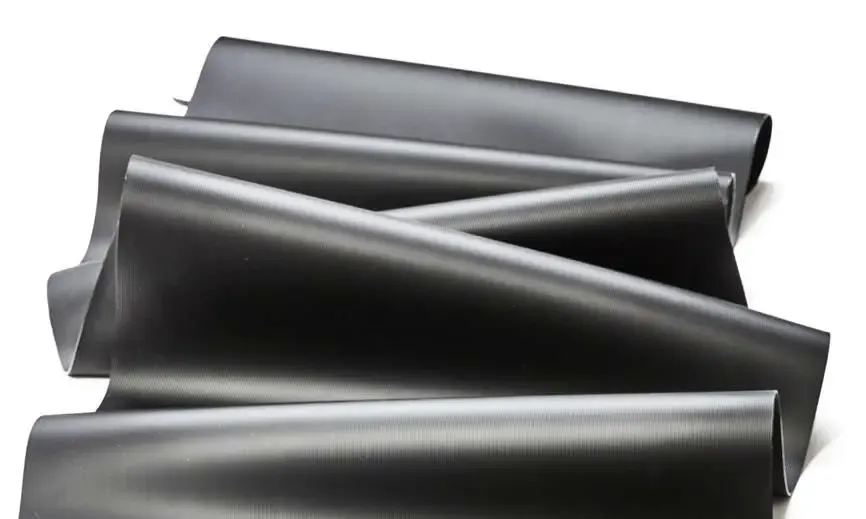

In the world of intralogistics and product transport in the food, pharmaceutical and packaging industries, choosing the right conveyor belt is key to ensuring safety, efficiency and durability. The elastic monolithic conveyor belts from BEHA with 2C technology (two components) are presented as an advanced solution that combines strength, adaptability and ease of maintenance.

What are double-component (2C) monolithic belts?

Unlike traditional multilayer belts, the monolithic BEHA belts are manufactured as a single homogeneous piece, eliminating the risk of layer separation or detachment of particles.

The innovation comes with 2C technology (two components), which makes it possible to manufacture a single belt with two different Shore hardness grades. For example:

- On the conveying side, a material with high grip ensures safe product movement, even on inclined conveyors.

- On the running side, a material with low friction improves energy efficiency and reduces wear.

This way, BEHAbelt offers the possibility of each side of the belt being optimized to perform a specific function, achieving superior performance.

Main advantages of BEHA belts with 2C technology

- Maximum process safety

- High resistance to abrasion and wear.

- Reliable performance in accumulation, inclination and continuous transport.

- Low noise generation, ideal for logistics environments.

- Flexibility and customization

- Thicknesses from 0.9 to 4 mm.

- Wide range of surfaces: smooth, rough, micro-structured.

- Optional special properties: antistatic, hydrolysis-resistant, flexible at low temperatures, UV-resistant or with antimicrobial additives.

- Hygiene and durability

- Monolithic construction that prevents bacteria build-up.

- Easy to clean, complying with food industry standards.

- Easy installation and maintenance

- Belts can be welded on-site using butt joint, with HS400 or HS800 welding systems.

- Reduced downtime and quick replacements.

Common applications

Thanks to their versatility, these belts are used in multiple sectors:

- Food industry: processing of meat, cheese, bakery, confectionery, fruits and vegetables.

- Intralogistics: sorting systems, accumulation and crossbelt sorters.

- Packaging: food and non-food packaging lines.

- Pharmaceutical and textile: safe and reliable transport in delicate processes.

The elastic monolithic conveyor belts with 2C technology represent a qualitative leap in industrial transport. Their two-component design combines optimal grip, low wear and easy maintenance, making them one of the most efficient and safest solutions on the market.

If you are looking to optimize your intralogistics or improve efficiency in food processes, these belts are a secure investment to reduce costs and increase productivity.

Do you want more technical information or a personalized recommendation for your sector? Contact us, official BEHAbelt distributor, and discover how these belts can improve your transport system.