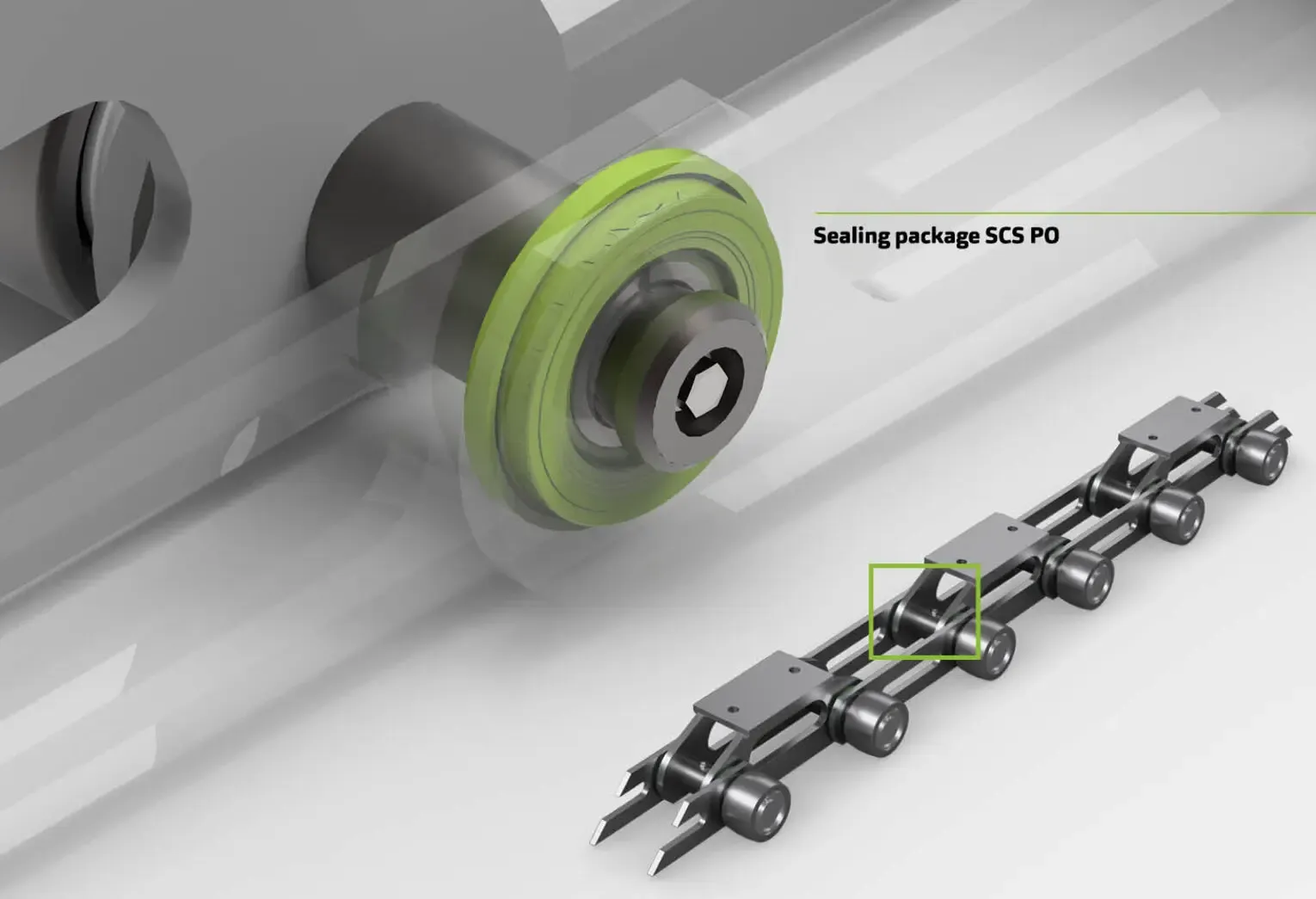

Cadena con lubricado permanente

KetenWulf develops the chain solution that enables continuous operation, without the need for grease maintenance and subsequent downtime. KettenWulf's SCS-PO chain technology seals the link joint and permanently eliminates relubrication. The result is less wear and more plant availability, even under very abrasive conditions.

What is SCS-PO?

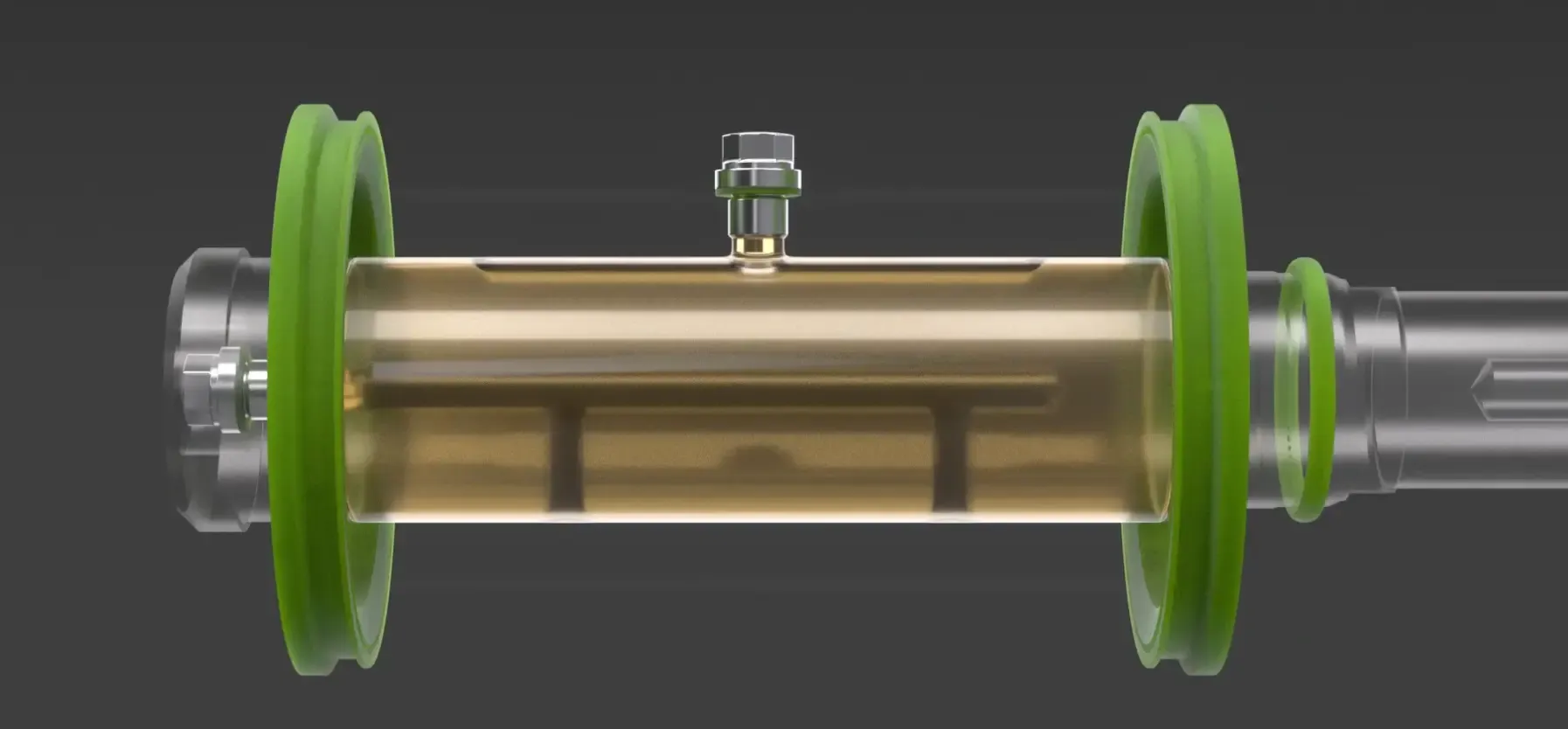

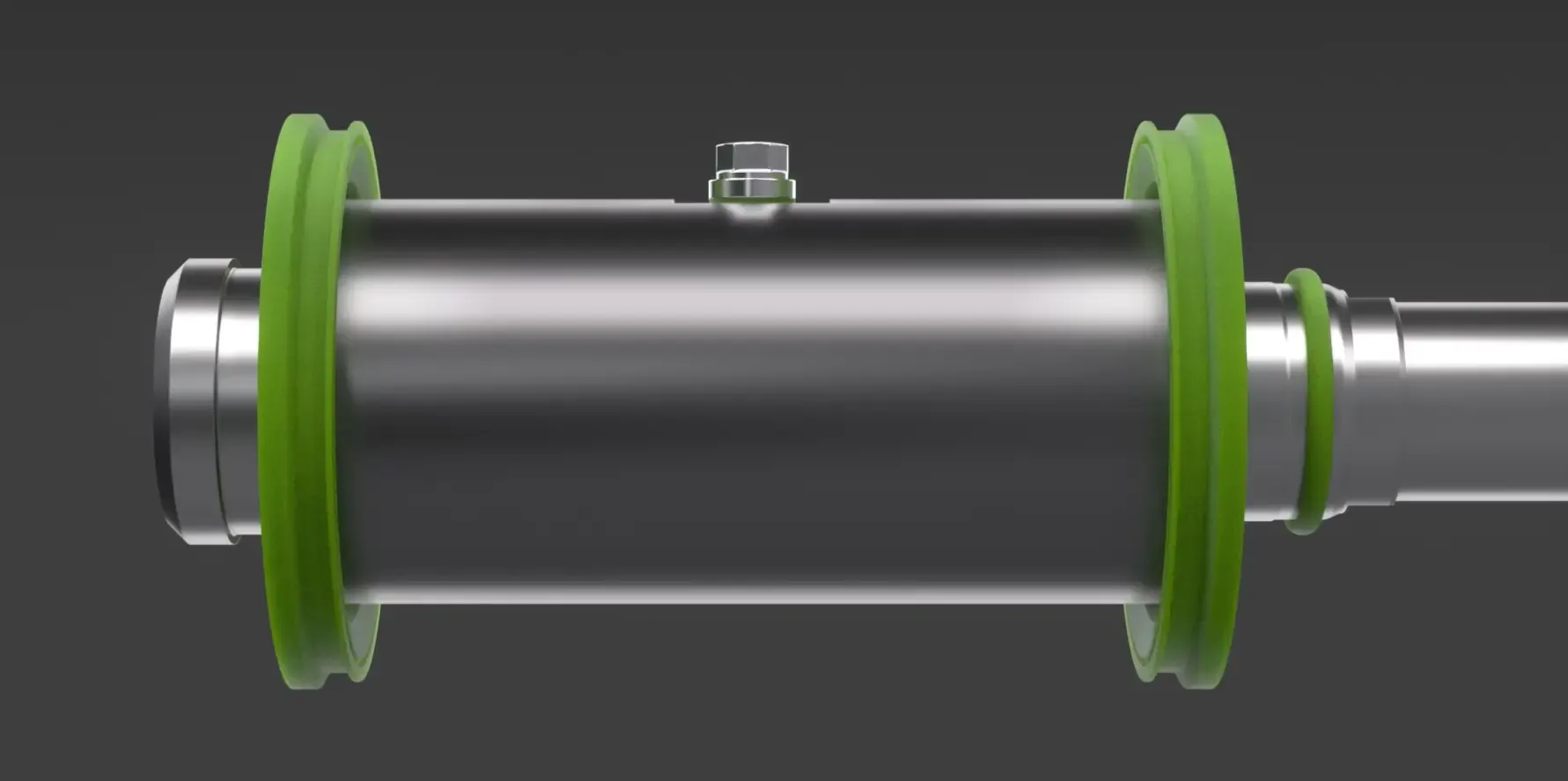

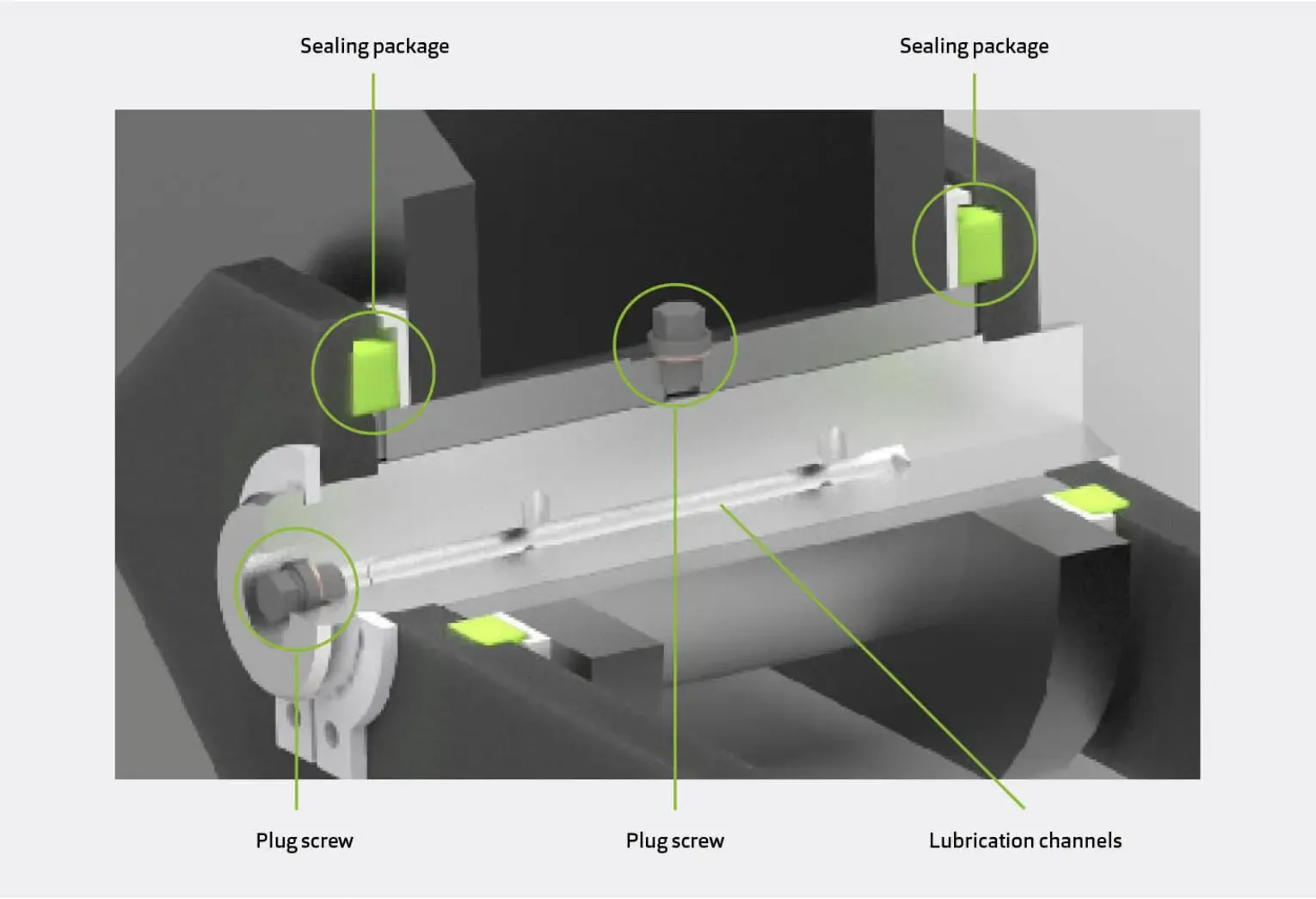

The Permanently Lubricated Sealed Chain System (SCS-PO) is a 100% oil-tight sealed link design – it keeps lubricant inside the pin and prevents contaminants from entering the joint. The system has been field-tested in harsh environments.

Key Benefits of the New Chain System

- No regreasing: periodic greasing tasks and inertias and associated errors disappear.

- Superior service life: Wear comparisons show "0 measurable wear" of the pin after more than 40,000 hours of heavy-duty operation.

- Lower total cost: fewer consumables, fewer downtime, and higher system availability.

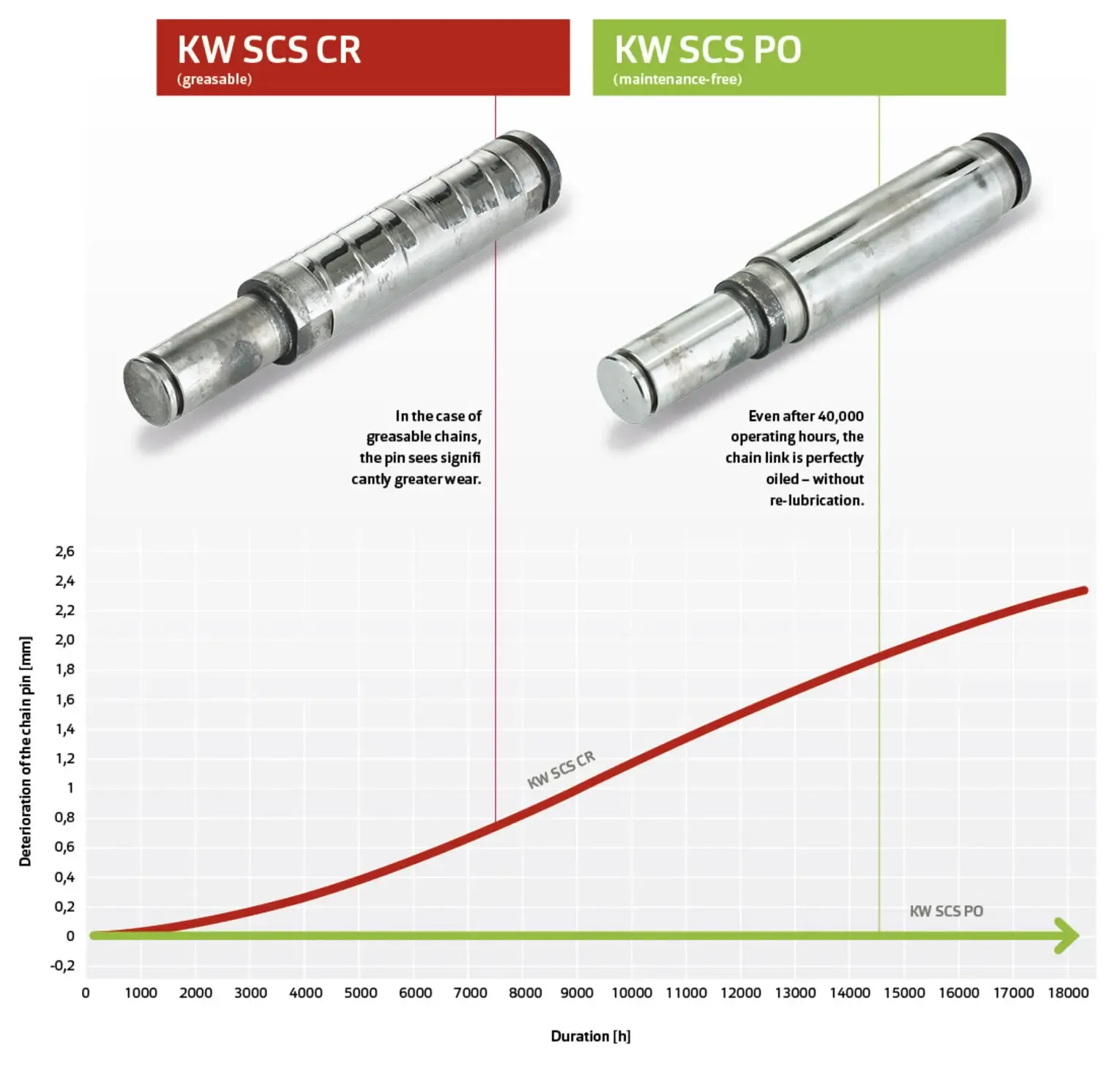

Comparison in pin wear

The pin used in the new sealing system, compared to the pin integrated in the standard chains, does not show appreciable wear.

Even after 40,000 hours of intensive work, the SCS PO chain pin stays lubricated without wearing out. With this minimization of maintenance, the installation of the new sealed chain system guarantees a significant reduction in time and costs.

Scope and applications

- Optimized for handling bulk solids (scrapers, reclaimers, tray conveyors...)

- With custom designs and detailed selection of sealing and lubricant packages according to process.

- Emergency greasing can be incorporated as an option.

- The system can be adapted to other sectors and types of chain.

KettenWulf SCS-PO chains are a proven solution that extends service life and reduces costs and downtime, allowing continuous operation. Contact us for a technical study and a proposal adapted to your installation.