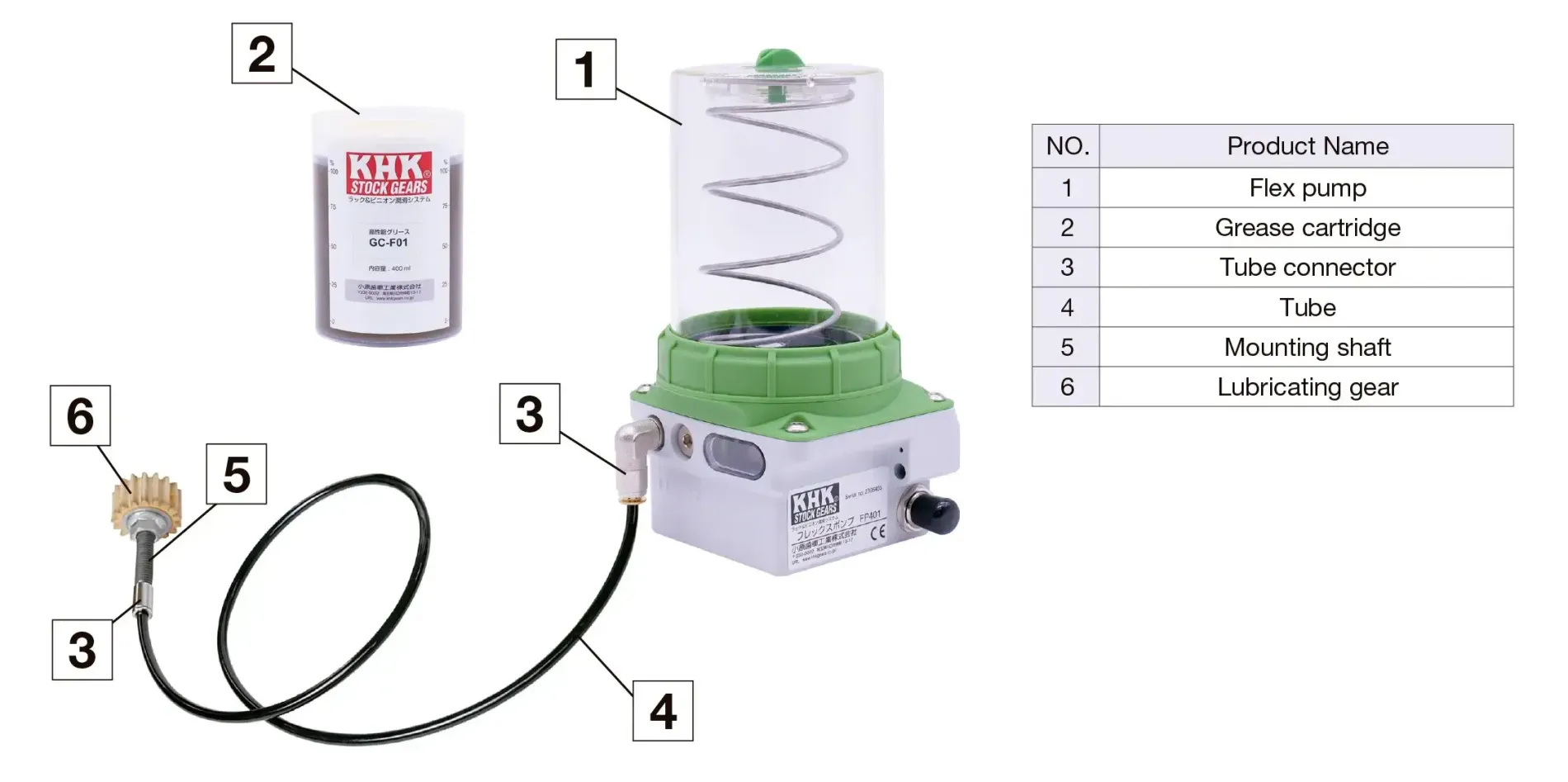

Rack and gear lubrication system

In mechanical systems where the gears and racks are used, maintaining proper lubrication is key to ensuring smooth operation, extending component lifespan, and minimizing unplanned downtime. The KHK lubrication system has been developed precisely for that purpose: to offer an effective, simple, and long-lasting solution for maintaining these systems.

Why is lubrication so important in rack and gear systems?

Constant friction between the gear and rack teeth causes wear, overheating, and loss of precision if not properly controlled. Poor or irregular lubrication can lead to:

-

Increased tooth wear

-

Abnormal noise and vibrations

-

Premature system failures

-

More frequent and costly maintenance

An automatic lubrication system helps prevent all these issues, significantly reducing long-term operating costs.

Technical features of the KHK lubrication system

The system consists of a series of components designed to easily adapt to various industrial applications. These are the main ones:

- Flex pump: Accurately doses the grease for continuous system lubrication.

- Grease cartridge: Replaceable container with special high-adhesion, heat-resistant grease.

- Tube connector: Metal connection between the pump and the grease transport tube.

- Tube: Polyamide conduit that carries the grease from the pump to the lubrication point.

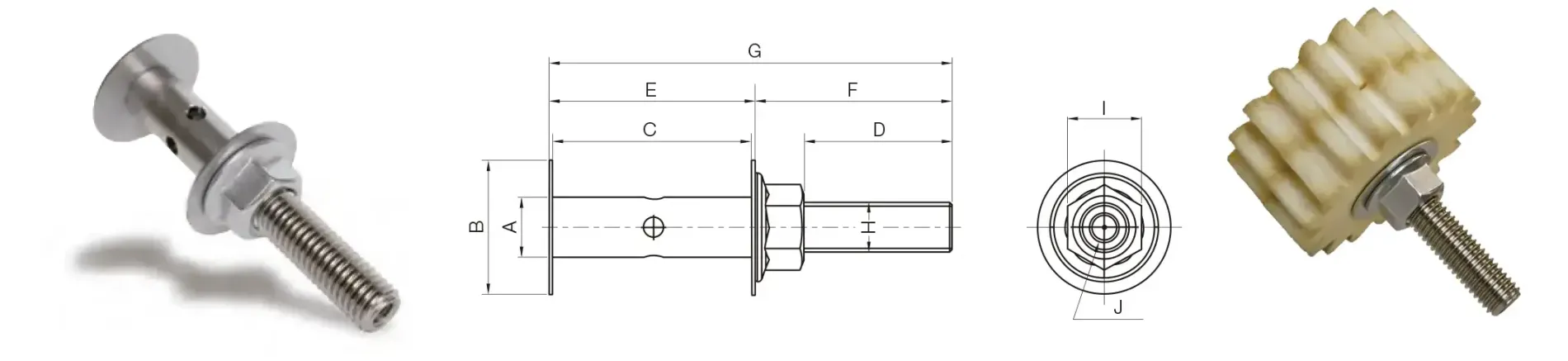

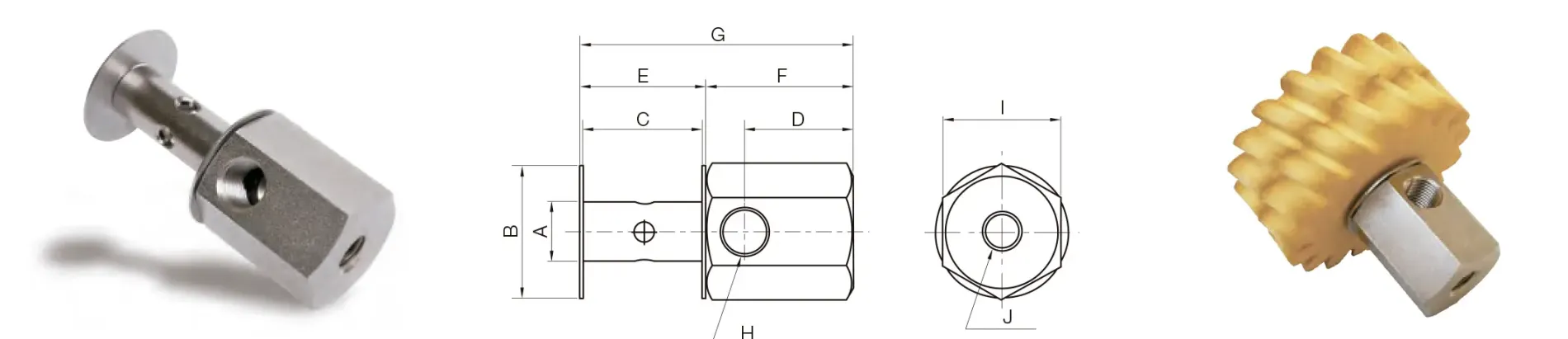

- Mounting shaft: Mechanical support that positions the lubricating gear in front of the rack.

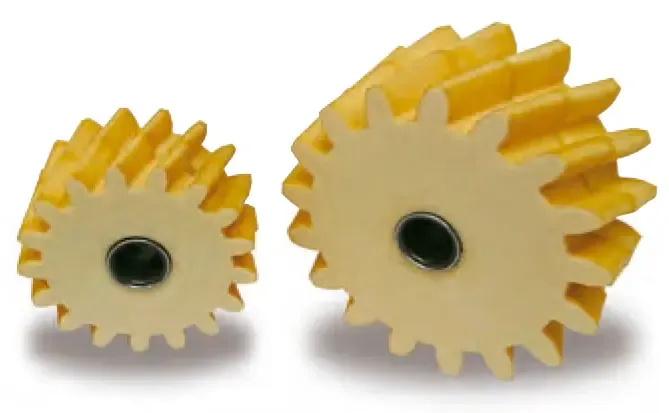

- Lubricating gear: Made of polyurethane, it applies grease evenly over the system's teeth.

This modular design allows for quick installation without the need to redesign the existing mechanical system.

Recommended gears for the lubrication system

- PUS/PUSCP Lubricated spur gear

- PUH Lubricated helical gear

Operational benefits

Implementing this lubrication system brings significant improvements in productivity, reliability, and cost-efficiency:

✅ Reduced corrective maintenance

✅ Improved system performance and precision

✅ Lower lubricant consumption thanks to controlled application

✅ Prevents contamination due to excess grease

✅ Longer lifespan of the rack-and-pinion assembly

Common industrial applications

The KHK rack and gear lubrication system is ideal for applications such as:

-

CNC machine tools

-

Industrial automation systems

-

Motorized industrial doors

-

Lifting and handling equipment

-

Assembly and conveyor lines

Why choose KHK Gears?

With over 85 years of experience in gear engineering, KHK Gears is a world-leading manufacturer of mechanical power transmission solutions. Their products are known for their precision, reliability, and compliance with the highest industrial standards.

Would you like to improve the efficiency of your rack and pinion systems?

At Lindis, we offer personalized advice and direct supply of the KHK lubrication system tailored to your specific needs. Contact us and we will assist you.