Choosing the right coupling in a servo motor system is not a minor detail. It directly affects accuracy, control stability, vibration, noise and, in many cases, cycle time. Within NBK’s catalog, two families stand out for covering most automation applications: XG couplings and XH couplings.

In this guide, we clearly explain when it makes sense to choose XG and when to choose XH, and what type of machine typically benefits from each solution.

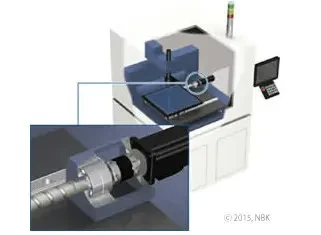

NBK XG Series Couplings: higher servo gain and shorter settling time

XG couplings are designed for applications where the goal is to increase servo gain and reduce settling time (settling time) without introducing oscillation or instability (hunting). This approach is especially useful when the machine needs to accelerate and decelerate quickly, but the system takes “too long” to settle. This often translates into direct productivity improvements when the cycle is short and repetitive.

When to choose an XG

XG is typically the best option if your priority is to:

- Reduce settling time to improve productivity.

- Prevent hunting when increasing control gain.

- Reduce vibration and noise in fast or repetitive movements.

- Maintain accurate transmission with practically zero backlash in positioning applications.

Common applications for XG series couplings

XG couplings are especially well suited to high-cycle machines and vision/measurement systems, where every millisecond of stabilization matters.

| Surface mount technology (SMT) | CNC vision measurement machine | Genetic analysis device |

|---|---|---|

| XGT2 | XGT2 | XGS2 |

|

|

|

| Press brake | Duplex image inspection machine | Single shaft actuator |

|---|---|---|

| XGT2 | XGT2 | XGS2 |

|

|

|

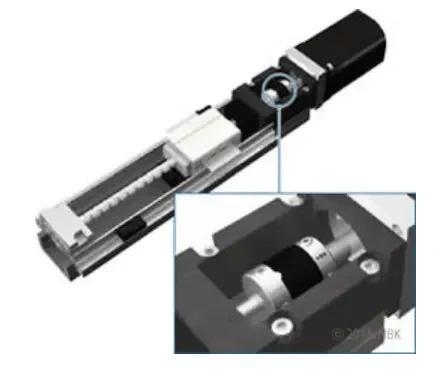

NBK XH Series Couplings: maximum torsional rigidity for torque and precision

The XH family (disc type) is focused on a different objective: maximum torsional rigidity. When the system requires a very direct response between motor and load—due to high torque, demanding positioning, or stable speed control—torsional rigidity becomes critical. In this scenario, the priority is reducing torsional deformation under load to maintain accuracy and repeatability.

When to choose an XH

XH is typically the best option if you need:

- High torsional rigidity to improve accuracy and repeatability.

- Transmit high torque (including peaks) with consistent behavior.

- High-speed, high-accuracy positioning.

- Stable speed control, minimizing torsional deformation under load.

Common applications for XH series couplings

XH couplings are common in automated assembly, systems with “harder” loads, and machines where torque and rigidity dominate the design.

| Diagnostic imaging device | Screen printing machine | Film deposition conveyance device |

|---|---|---|

| XHW-C | XHS | XHW-C-L |

|

|

|

Key differences between XG couplings and XH couplings

Key points to consider when choosing between an XG coupling and an XH coupling:

- XG: When the challenge is dynamic (gain, stability, vibration, settling time). It prioritizes stability, damping and reduced settling time when you need to increase servo gain without hunting.

- XH: When the challenge is mechanical/torsional (torque, rigidity, precision under load). It prioritizes torsional rigidity and torque when you need very direct transmission and high precision under load.

What data do you need to choose the correct model?

To select the exact model (not just the series), you should review:

- Rated torque and peak torque

- RPM

- Shaft diameter (bore)

- Allowable misalignment

- Length and space constraints

- Load inertia and cycle dynamics

With this data, you can refine the selection using sound technical criteria and avoid oversizing. In addition, you reduce typical risks such as residual vibration, coupling overload, or repeatability loss in high-cycle applications.

Are you optimizing a machine and unsure whether to choose XG or XH? At Lindis, we help you select the right NBK coupling for your servo motor system (torque, rigidity, misalignment, and installation constraints).

Request technical advice and we will propose the most suitable option for your application.