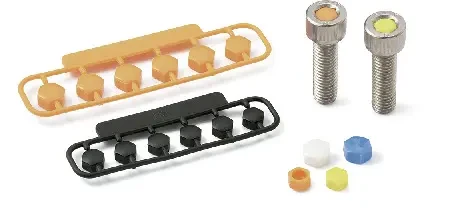

In many machines and industrial assemblies, hex socket screws (Allen screws) are installed with the drive recess exposed. In environments with dust, chips, splashes, or frequent cleaning, the hex socket tends to accumulate dirt, which complicates maintenance and can affect the overall reliability of the assembly. In applications with strict hygiene or contamination control requirements, these cavities can also become particle retention points, with a direct impact on process safety and inspection outcomes. For these scenarios, NBK offers protective caps and plugs for hex socket screws, designed to fit into the hexagonal recess of the screw and protect the drive.

Drive protection and control against tampering

NBK recessed caps are inserted into the hex socket with a precise fit. By covering the drive, they restrict direct access to the tool, helping to prevent unauthorized manipulation or accidental disassembly. This approach is especially useful in equipment where maintaining a stable adjustment after commissioning or limiting unplanned interventions is required.

Faster cleaning and reduced risk of contamination

Models such as SRRIP help keep dust and dirt out of the hex socket, reducing the accumulation of residues inside the drive. This facilitates cleaning, improves the repeatability of maintenance tasks, and lowers the risk of particles or foreign matter being dispersed during washing or service operations. In hygiene-critical industries, this contributes to a more controlled environment and more consistent inspections.

Visual identification of screws and critical points

In addition to protection, these caps can be used for screw marking and identification: they make it easy to quickly recognize adjustment points, verified screws, or areas that should not be manipulated, reducing maintenance errors and speeding up inspections.

Precautions for use

Once installed, the cover can be removed with a thin tool when necessary. To preserve its integrity and ensure a proper fit, it is recommended to handle it carefully; and if the cover is damaged, it must be replaced with a new one to guarantee secure retention. In addition, depending on the operating conditions, it is advisable to validate its performance by carrying out a prior test under real conditions, confirming that it maintains the expected retention and functionality.

A simple add-on with a direct impact on reliability

The NBK protective caps for Allen / hex socket screws integrate easily without modifying the screw or the assembly process, providing drive protection, improved cleanliness, support for identification, and greater control against tampering.

As an NBK distributor, Lindis can help you select the most suitable reference according to the screw type and the operating environment.