At Lindis we offer, through new technological processes, the personalized manufacturing of slip-free conveyor belts, with a width of up to 700 mm.

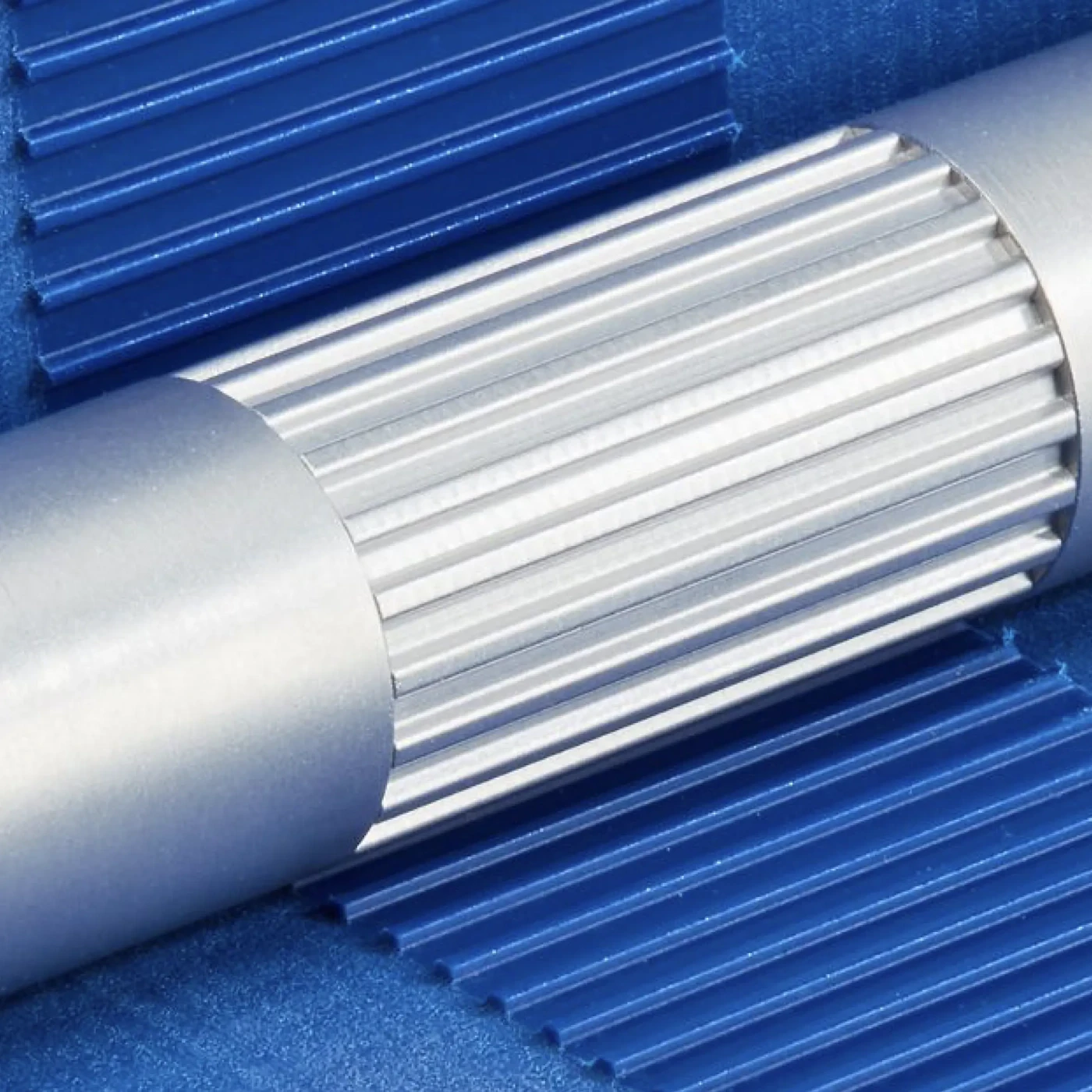

Thanks to the flexibility of the AT5 anti-slip belts and the option of reverse machining on its toothed base, it is possible to design equipment with very small diameter pulleys. This, in addition to saving costs, also allows the spacing between belts to be reduced, facilitating the transport of food products from one belt to another.

Now FDA belts, with different functional surfaces for the food sector, can become custom-designed synchronous belts, adapting to the most specific needs.

Thanks to the flexibility of the AT5 anti-slip belts and the option of reverse machining on its toothed base, it is possible to design equipment with very small diameter pulleys. This, in addition to saving costs, also allows the spacing between belts to be reduced, facilitating the transport of food products from one belt to another.

Now FDA belts, with different functional surfaces for the food sector, can become custom-designed synchronous belts, adapting to the most specific needs.