- Backlash-free instant disengagement: the ball-and-spring system enables fast, precise decoupling in overload situations.

- Adjustable disengagement torque: can be configured to suit specific application needs.

- 360° automatic re-engagement: the coupling resets itself automatically once normal conditions return.

- Misalignment compensation: absorbs axial, radial and angular misalignments.

- Maintenance-free design: robust construction ensures long service life without the need for routine adjustments.

Safety Couplings

No results

Description

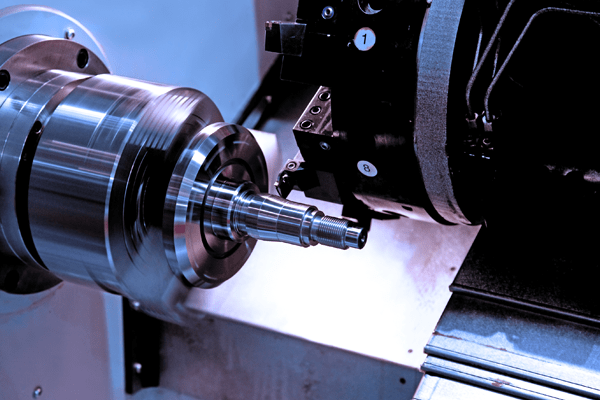

Safety couplings with torque limiter are critical components for protecting mechanical systems against overloads, collisions, or unexpected blockages. Designed to immediately disengage torque transmission when a preset limit is exceeded, these couplings help prevent damage to machinery and minimise downtime.

Key Technical Features

Common Applications

These couplings are ideal for sectors where safety and precision are critical:

- Industrial automation and robotics

- Packaging and processing machinery

- Conveyors and material handling systems

- CNC machines and tooling

- Food and pharmaceutical industries

Safety Coupling Types

- Rigid Couplings: offer a solid, zero-play shaft connection with no vibration absorption.

- Torque Limiter Couplings: include built-in overload protection mechanisms.

- Bellows Couplings: ideal for dynamic applications such as servomotors, ball screws, and industrial robots thanks to their high precision and alignment compensation.

Competitive Advantages

- Accurate, backlash-free torque transmission

- Effective protection against overloads

- Adaptable to various shaft configurations

- Reduced maintenance and repair costs

- Enhanced operational safety and machinery lifespan